|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Springfield Armory M1 Rifle Serial # 177XXX (December 1940)

|

| Rear

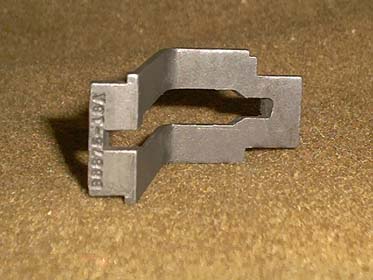

Sight Assembly

The earliest M1 rifles were equipped with what is referred to as a "flush nut" rear sight. This early rear sight assembly consisted of the rear sight base, the rear sight aperture, a short pinion, a rear sight spring cover, the elevation cap, the windage knob, a spring/detent assembly and the flush nut. The earliest versions of rear sights (most often on gas trap M1s) will often have parts numbered with the drawing number. On this particular rifle, serial # 177XXX from approximately December of 1940, none of the sight parts are numbered. The elevation cap is checkered, as is the windage knob - later versions were knurled. The flush nut was eventually abandoned as it was prone to becoming loose and falling off, rendering the rear sight useless. Not exactly what you'd want to have happen in the middle of a battle! Flush nut rear sights were used from beginning of production to approximately early 1942. |

|

| Bolt

Assembly

The bolts of M1 rifles underwent many revision changes, just as the other parts did. The earliest bolts, for gas trap rifles, either did not have a revision number, or were revision-1. This December 1940, an early gas port rifle, sports a revision-2 springfield Armory bolt. Found on the bolt is the drawing number (D28287) and the revision number (-2SA), followed by the heat lot (in this case "J8"). The early -2 bolts are known for being the longest bolts, and shooters will often use these bolts to correct excessive headspace in their rifles. The early M1 rifles had firing pins that were completely round, or solid, across the entire body. It was found that these pins tended to jam, and thus, later firing pins were milled in half cross-sectionally. The firing pins, as well as extractors on early M1 bolts were a blued finish. I'm still trying to check the validity of the firing pin in this photo, as I believe it may be a reproduction. |

|

|

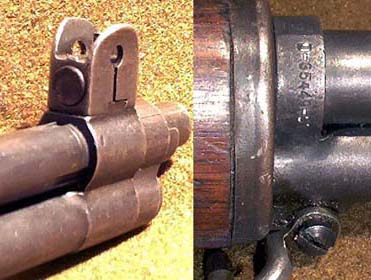

| Barrel/Operating

Rod Assembly

The barrel on WWII M1s had the manufacture date (manufacture of the barrel, not the complete rifle) stamped onto the side facing the operating rod. On barrels up until about 11-42, the date was stamped upside down, after 11-42, the dates were stamped right-side up. Accompanying the barrel date on original rifles will be a proof mark "P" with a punch-mark inside the loop of the "P". This is the firing proof. The pads around the gas port on original finish WWII barrels will be parkerized, like the rest of the barrel. After the war, these pads were often chromed as a part of the arsenal rebuild and repair program. The operating rod is blown back by the gas vented through the barrel's gas port after a shell is fired. It drives the bolt back, cocking the hammer, and loading the next round on the forward stroke. This revision-2 op rod has the 3/16 inch radius field modification cut. Original design WWII op rods do not have this radiused cut - they have metal going straight across. These cuts were made because the force generated by launching grenades from the M1 could crack an uncut rod. Post WWII rods were manufactured with the radius cut. |

|

|

|

These pictures show a close-up and a full length view of the type 2 follower rod. The full round-bodied type 2 follower rods were used for only a brief time from approximately late October 1940 to approximately January 1941, and are quite difficult to find now. This type of follower rod came after the type 1, which was developed for use with the keystone shaped op rod spring and compensating springs that were of the original design (mainly used in gas trap Garands). The main difference from the type 1 rods is that the "rim" of the rod which the operating rod spring rests against is moved toward the back of the rod, due to the lack of a compensating spring. On this rifle, the spring is the round-coiled type found on most M1 Garands. The milled-type follower rods would eventually be replaced by stamped and riveted rods to speed up production. These rods will be shown on several other rifles later in the website. |

|

|

| Internal Receiver

Parts

Within the receiver itself is the follower, follower arm, bullet guide and op rod catch. These parts serve as the operating mechanism to align and feed the cartridges from the 8 round en bloc clip into the chamber. Changes occured in the production of these parts, like all parts, to improve the efficiency of both the rifle, and to speed up production time. On this particular rifle, the follower assembly is unmarked, and exhibits the "narrow tail" found on early production followers. Continuing clockwise is the early single bevel follower arm, milled bullet guide with part number "B8875-1SA", and the unmarked, early type operating rod catch. |

|

|

|

| >

| Gas Cylinder

The gas cylinder is located on the "business end" of the M1 rifle. Early M1 gas cylinders were stamped with the drawing number "D-35449-SA" on the right side of the rear ring. Like many of the numbered parts, stamping the number on the cylinder ring was eventually done away with. The front sight base was narrow profile, and the front sight screw was covered by a sight seal to prevent unauthorized adjustment of the front sight. The narrow sight bases proved to be unsuitable, as they reduced the distance the sight could be moved to render the rifle serviceable. There was also a tendency for the gas cylinder to loosen on the barrel, which would cause the point of bullet impact to drift. This problem was temporarily corrected by removing the sight seal and cutting downward through the sight base. When the front sight was re-attached to the cut base, it "pinched" upon the base, causing the cylinder to draw up tighter on the barrel. Two types of saw-cut cylinders are encountered: the straight-cut, and the diagonal cut. In mid-1943, the sight base was widened to further correct the adjustability of the front sight. |

|

| Stock

The stocks on M1 Garands were made of American Walnut with a linseed oil finish. Early M1 stocks (up to early 1942) have what are referred to as "long-channel" stocks, or stocks in which the very end of the barrel channel measures 2 3/8 inches long (see top left picture). After early 1942, some of these long channel stocks were modified and cut down to short channel (1 5/8 inches) configuration. Notice that the front stock ferrule is the stamped type with no hole. Early stocks also exhibit numbers stamped within the barrel channel. To date, I have found no sources that offer an explanation as to what these numbers mean. As seen in the top right photo, this December 1940 stock has the number "36" stamped in the barrel channel. |

|

|

| Perhaps the part of the stock that seems to be the most "important" to Garand collectors is the cartouche. The cartouche consisted of the armory letters (in this case, "S.A." for Sprigfield Armory), followed by the initials of the Commanding Officer of the armory at the time (here, "G.H.S." for Brigadier General Gilbert H. Stewart), stamped into the stock on the left-hand side just under where the receiver heel. Usually, the ordnance wheel, or "crossed cannons" was placed directly behind the boxed initials. The crossed cannons on this GHS stock is the large wheel variety. Due to over 60 years of use, many cartouches have been obliterated throughout the years. Many were sanded away. As a result, cartouched wood can be difficult to find today, and usually commands a premium price, especially for the earlier cartouches. Because of this, stocks with counterfeit cartouches are becoming common. Each type of stock has characteristics other than the cartouche that will tell the collector what it really is (and to avoid giving the counterfeiters this information, I will not discuss those characteristics here). To avoid being taken by a fake stock, READ the literature, and handle as many real stocks as you can from reputable sources. |

|